For Engineer

Experiment: prevent rust inside steel pipe by magnetic method

1.Oxygen enters the system:

-

- Filling the water to the system

- Opened type expansion tank

- Air vent valve (when the system prssure is vacuum)

- Air osmosis through the diagram of the closed expansion tank

- Water make up

-

2.Iron oxide amount in the system calculating for a closed expansion tank air charging cycle (about 6 months):

- Water filling: 40 grams of Fe3O4 / 1 cubic meter of water

- The air is trapped in pipes: 45 grams of Fe3O4 / 1 cubic meter of water

- Air osmosis through the diagram of the closed expansion tank: 435 grams of Fe3O4 / 1 cubic meter of water

- On average, each 1 cubic meter of water produces 520 grams of Fe3O4 rust and 165 Liters of Nitrogen

-

3.Rust problems:

- Rust make a layer inside the coil FCU, AHU, PAU, Chiller, ... leads to reduce heat transfer ability, reduces equipment capacity andreduces system performance, increases power consumption

-

- The more rust is made, the more pipe corrosion

- Rust precipitates on the valve surface, causes damage to the valve, especially the PICV balancing valves will not be functional properlly.

-

4.Nitrogen problems:

- Nitrogen bubble in FCU, AHU, PAU coils ... leads to reduce heat transfer area, reduce capacity, and increase water pressure drop, reduce system efficiency

- Nitrogen bubble causes valve collisions, make noise and equipment damage, and shorten system life

-

5.Oxygen in water reacts with iron material of pipeline to make Fe3o4 (black), Fe2O3 (orange red):

-

· Fe2O3

· Fe3O4

1.

6.When the water opens to atmosphere (same situation to the opened type expansion tank solution), the oxygen in water reacts with iron, the oxygen in water is supplied from the atmosphere all the time, reaction will give Fe2O3 red oxide

2.

3.

9.Ferrous oxide black Fe3O4, when contact to atmosphere, will slowly change to FE2O3, the reaction will be faster if it happens in electrolyte environment by adding some NaCl

10.Boiling the water, then put into iron pipe, covered, after 24 hours, only little iron oxide Fe3O4 made, this means that the higher temperature water, the smaller air absorbed in the water.

6. 11.Fe2O3 iron oxide is not attracted by magnets

12.Fe3O4 iron oxide is attracted by the magnet, so a magnet dirt separator can be used

7. 13.Solutions to help prevent rust and remove the dirt in water pipe:

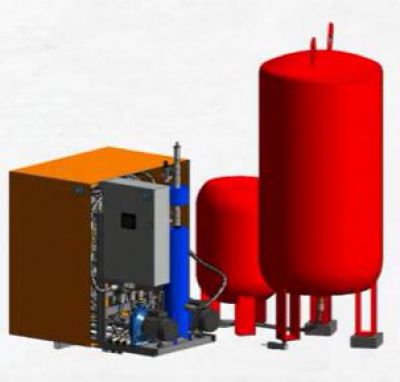

Prevent Oxygen from contacting the water: use a pressurisation system instead of the expansion tank solution

Use the vacuum air separator of the pressurisation system to remove all air (bubble and absorbed) in the water. No oxygen in the water, no reaction to create iron oxide, no dirt in the water.

Using the pressurisation system, the oxygen present, if have, is very low, this poor amount of oxygen produces only small amount of Fe3O4 oxide (black) in water, which can be removed by using the magnet easily and bring it out of the system.

In addition, the pressurisation system also have other functions:

§ Water pressure maintenance: use pump(s), pressure sensor to keep the pressure stable

§ Continuous, efficiency, cyclonic vacuum air separator: air is removed in vacuum pressure and all modes of operation.

§ Water make up: control the water make up automatically and remove all air in make up water § Magnetic dirt separator

§ 60 micron filter (Optional)

§ Water Treatment with UV Irradiation (Optional): kill viruses and bacteria

Design web by WebMinhThuan.Com